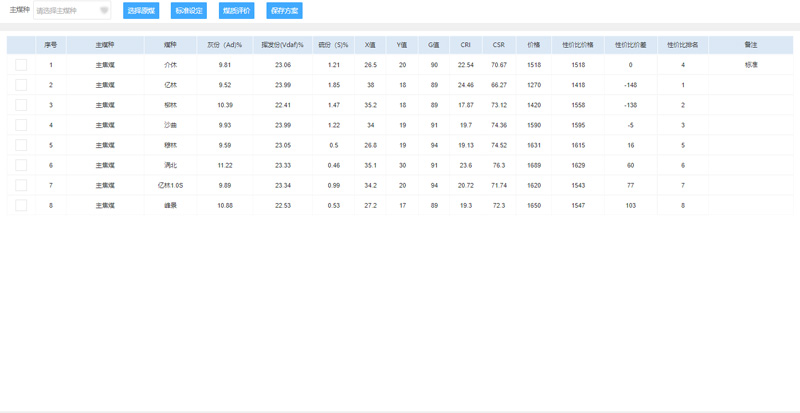

Coal quality evaluation: according to various indicators of each single coal, small coke oven test results, and in combination with actual production coal sources, the system calculates the cost performance ratio of each coal based on the set standard coal, and ranks the cost performance ratio for reference by the procurement and production departments.

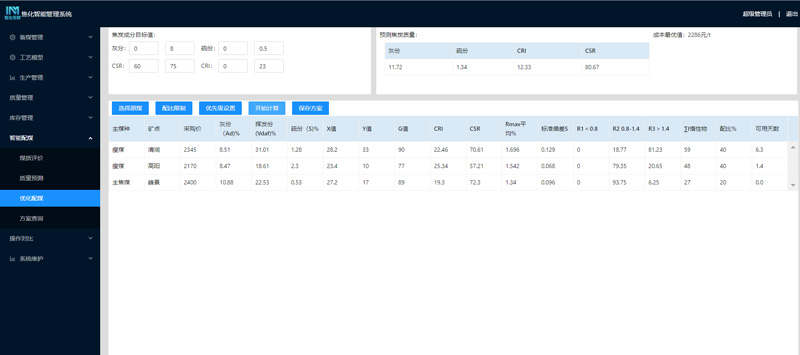

Coke quality prediction: using the rich experience and experimental data accumulated by coking and coal blending experts, combined with a large number of successful historical coal blending and coking data accumulated in actual production, and using the correlation analysis method of coal rock coal blending, find out the correlation between single coal, blended coal and coke quality, so as to ensure that production management personnel can quickly and widely select coal sources and stabilize coke quality under normal production conditions.

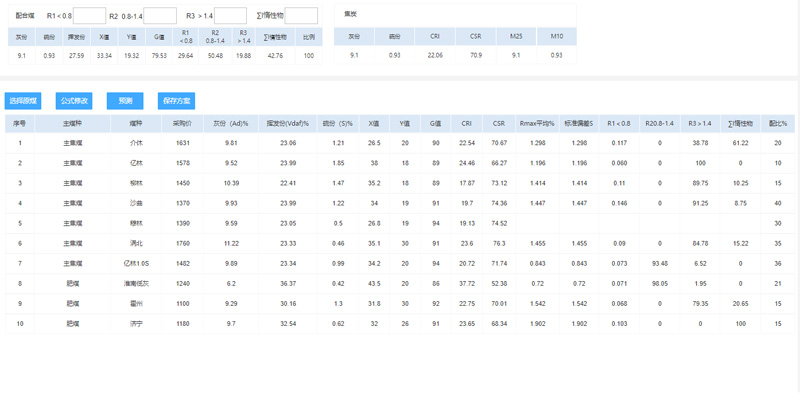

Optimized coal blending: according to the given coke quality index requirements, the existing single coal quality data of the coking plant, the given cost and inventory and other constraints, multiple machine learning algorithms such as genetic algorithm, differential evolution algorithm and optimization optimization are comprehensively used to comprehensively optimize and calculate multiple groups of coal blending schemes, and the lowest cost coal blending schemes are output in order for users to refer to and make decisions.

Prev: Production report

Next: Inventory management