High quality intelligent products, services and solutions

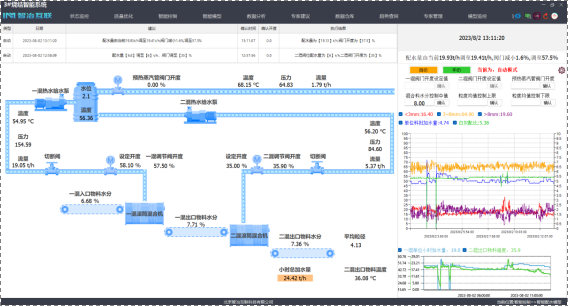

The sintering mixture moisture and particle size distribution monitoring technology, which combines image particle size distribution recognition technology, big data intelligent algorithms, and online microwave moisture detector, is a patented technology independently developed by our company. It is also the latest technology independently created and first applied in sintering ore production in China. Currently, it is at a leading level both domestically and internationally.

This technology mainly uses image recognition, statistical particle size distribution, and combines online moisture detection to establish an intelligent control model for the range of mixed material particle size distribution and water content. By controlling the range of particle size distribution, the water content of the mixed material is controlled and the automatic adjustment of water content is achieved, achieving online detection of mixed material water content while detecting particle size distribution. Therefore, the detection of mixed material water content and particle size distribution recognition are organically integrated, forming a sintering intelligent water distribution technology that focuses on controlling particle size and supplemented by water content detection. It can control the amount of water added and the optimal control range of particle size in real time and accurately, making the water content adjustment of sintered mixed materials more controllable and responsive.

Technical highlights:

● Accuracy: The image granularity recognition method is based on a large amount of data, and its scanned material surface has stability and representativeness, which can avoid the fluctuation impact caused by simple moisture detection;

Timeliness: It realizes online real-time detection of moisture and particle size distribution in the mixture, making production response faster and adjustment more timely;

● Intelligence: The image recognition monitoring model based on artificial neural technology has self-learning ability and can meet the detection requirements under different production states;

Stability: By controlling the particle size of the mixture to control moisture, the goal is clearer, the adjustment is more stable, and the control effect is better.

System implementation goals:

Stabilize the particle size distribution of the mixture, improve the permeability of the material layer, stabilize production, increase production, reduce fuel consumption, and lower electricity consumption

Prev: period

Next: period