In view of the complexity (multifaceted), nonlinear (irregular), time-varying (time varying), hysteresis (thermal inertia) and other factors of coke oven heating, in order to avoid unnecessary furnace temperature fluctuations caused by frequent and excessive adjustments, on the premise of maintaining relatively stable heat supply and furnace temperature, in line with the principles of practicality, effectiveness and scientificity, the fire down time is taken as the control target and furnace temperature is adjusted as the means, Give consideration to the combination of automatic and manual, and conduct periodic temperature control according to the coke oven heating law to achieve effective temperature control effect.

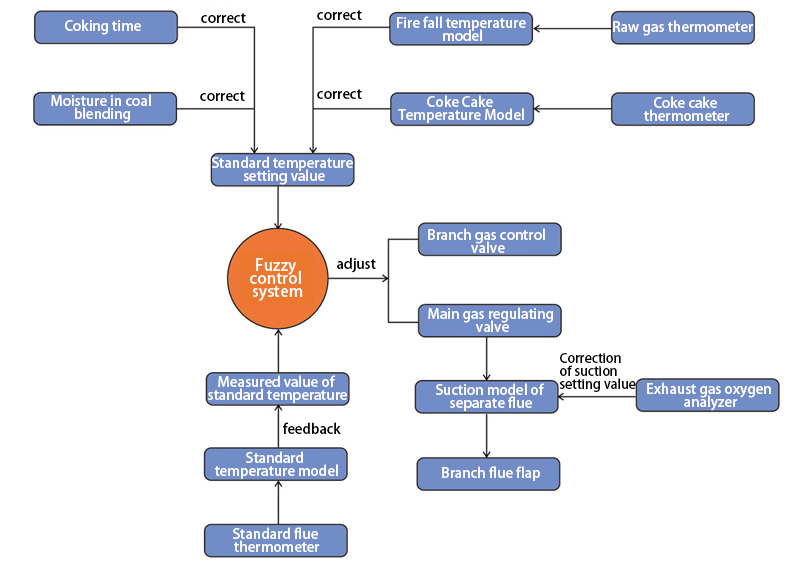

This coke oven heating intelligent heating system is based on the straight temperature automatic temperature measurement system, coke cake surface temperature measurement, fire fall management system and heating gas branch pipe automatic regulation system. By using modern control technology, the four are integrated to achieve more scientific, reasonable, practical and effective coke oven heating optimization and temperature control:

1. Determine the target fire falling time according to the coking cycle and coke quality index statistics;

2. Determine the target standard flue temperature according to the target fire falling time;

3. According to the target standard flue temperature and coke oven heating law, control the branch pipe gas flow and flue suction;

4. Optimize the flue suction control value according to the online monitoring of exhaust gas oxygen content;

5. Correct the standard temperature control value according to the central temperature of the coke cake and the fire falling time.

System energy efficiency:

1. Reduce energy consumption: save 2% - 6% of coke oven heating gas.

2. Improve operation efficiency: reduce labor cost, reduce labor intensity of workers, and improve operation efficiency.

3. Improve coke quality: the furnace temperature is effectively controlled, the temperature is timely adjusted, and the coke product quality is improved.

4. Reduction of nitrogen oxide production: optimizing temperature control can reduce the standard temperature by 10 ° C-20 ° C, reduce the production of nitrogen oxides from the source, and reduce the operation cost of flue gas denitrification.

5. Improve the recovery rate of by-products: with the improvement of furnace temperature, the recovery rate of chemical products will be increased accordingly.

Prev: Real time monitoring of straight standard temperature

Next: period