System introduction:

Traditional coke oven temperature measurement and heating generally adopt manual measurement of standard flue temperature, with long interval time and large temperature measurement error, which can not meet the needs of real-time monitoring (especially frequent change of coking time) of furnace temperature change during coking process, and it is time-consuming.

System functions:

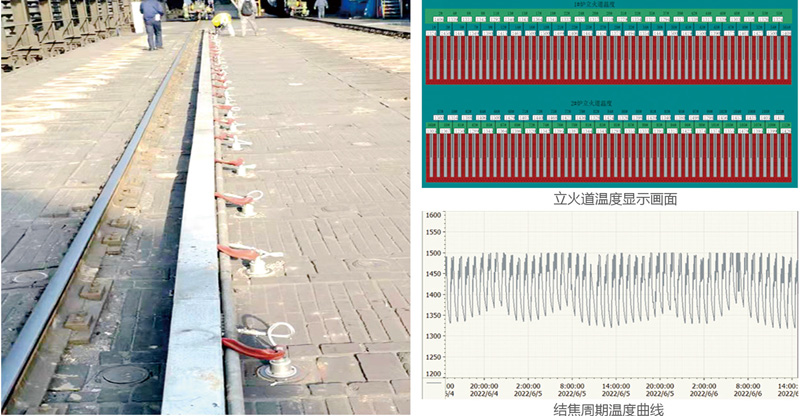

1. Realize 24-hour online real-time monitoring, which can monitor furnace temperature dynamics at any time, and timely find furnace temperature anomalies;

2. According to the feedback of online monitoring temperature signal, the main pipe gas flow can be automatically adjusted;

3. Automatically generate temperature trend curve of coking period of each combustion chamber and straight temperature curve of the whole furnace, which can timely find high and low temperature furnace number;

4. Automatically calculate the stability coefficient and uniformity coefficient of the straight temperature, and evaluate the stability and uniformity of the whole furnace standard temperature;

5. The collected data can automatically convert the temperature 20 seconds after the change, and automatically calculate the average temperature of the whole furnace at the coke side and the temperature difference at the coke side of each combustion chamber;

6. It can read the horizontal data of the manual thermometer, form complete data in the automatic temperature measurement system, and generate a query report.

Equipment parameters:

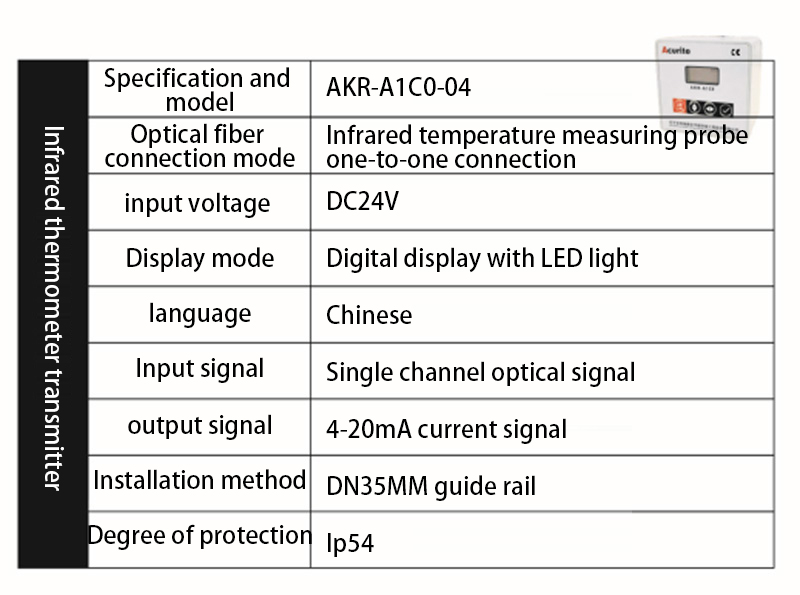

Infrared thermometer transmitter:

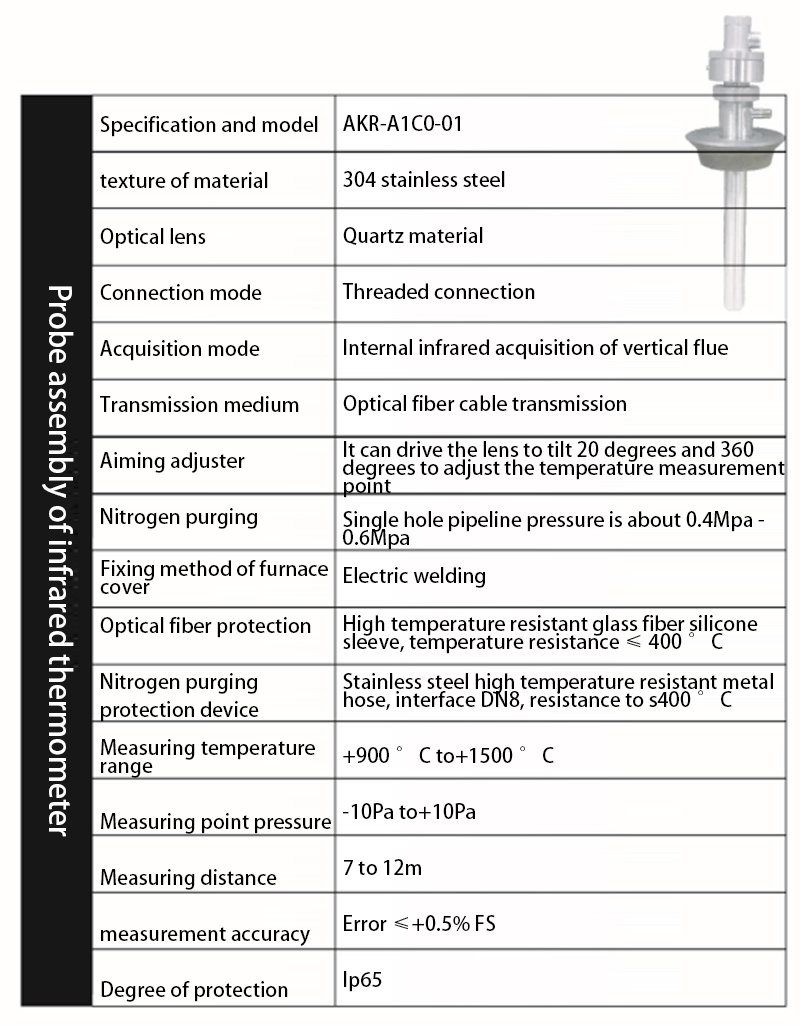

Infrared thermometer lens assembly: